Welcome to Suzhou Texu Precision Machinery Co., Ltd. official website!

Flat-bottom probe

Probe characteristicsCommon structure of the probetraitLong service time, 10,000 timesNo mold fees, easy to customizeAdjustable and measurable spring forceFine spacingFlexible manufacturing methods. SMT, plug-in...Space saving: Helps mechanical engineers easily distribute components on t

产品描述

Probe characteristics

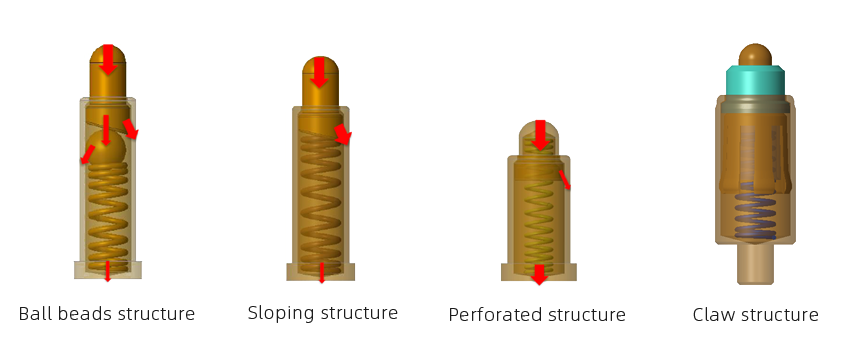

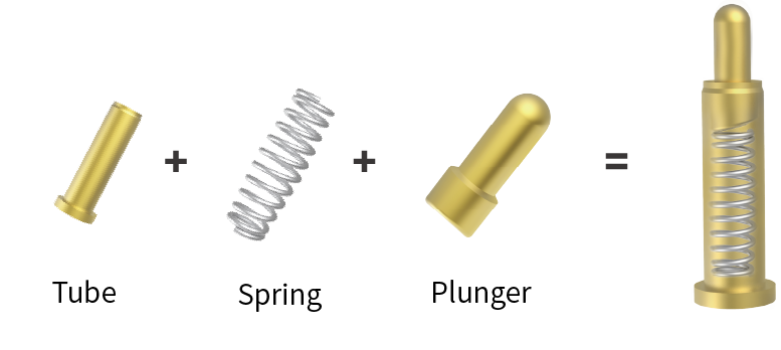

Common structure of the probe

trait

Long service time, 10,000 times

No mold fees, easy to customize

Adjustable and measurable spring force

Fine spacing

Flexible manufacturing methods. SMT, plug-in...

Space saving: Helps mechanical engineers easily distribute components on the PCB

Performs well in RF solutions

RoHS and halogen-free

Common internal structure of the probe st

st

| structure | Spherulo-bead structure | Inclined structure | Perforated structure | Claw structure |

| Contact impedance | ≤ 10mΩ | ≤ 30mΩ | ≤ 50mΩ | ≤ 5mΩ |

| Long service time | 10000+ | 10000+ | 10000+ | 500+ |

| Recommended operating current | 10A max | 10A max | 10A max | 10A max |

| Linkage stability | ★ ★ ★ ★ ☆ | ★ ★ ★ ☆ ☆ | ★ ★ ★ ☆ ☆ | ★ ★ ★ ★ ★ |

| Handling charge | ★ ★ ★ ☆ ☆ | ★ ★ ☆ ☆ ☆ | ★ ★ ☆ ☆ ☆ | ★ ★ ★ ★ ☆ |

| Main application field | It is mainly used for charging and conditions that have certain requirements for vibration and shock. | Mainly used for charging or signal transmission of consumer electronic products | It is mainly used for signal transmission or antenna grounding. | Mainly used in high-frequency, anti-instantaneous, need high reliability occasions, such as base stations, military, vehicles. |

| remark | Beads increase the internal contact, the contact is more stable, and more pinhole space is required. | The most commonly used structure on the market | The space is small, but the contact is unstable, the current is easy to run through the spring, and it is not recommended for charging. | Needles and tubes have multiple contacts to increase contact stability |

Product model

| index | Part No. | ∅ A | B | C | D | E | Force(gf) | |

| 1 | 20101011233 | 1.2 | 0.6 | 1.45 | 1.95 | 1.6 | 35gf Min | |

| 2 | 101245-1 | 2 | 0.4 | 2.2 | 3 | 2.4 | 90 Min | |

| 3 | 10101011363 | 1.8 | 0.5 | 2.3 | 3 | 2.5 | 90 Min | |

| 4 | 101089-1 | 1.65 | 0.4 | 2.2 | 3 | 2.5 | 90 Min | |

| 5 | 101603-1 | 1.65 | 0.4 | 2.2 | 3 | 2.5 | 90 Min | |

| 6 | 101022-1 | 1.65 | 0.6 | 2.4 | 3.2 | 2.7 | 90 Min | |

| 7 | 101080-1 | 1.8 | 0.4 | 2.5 | 3.3 | 2.8 | 90±20 | |

| 8 | 101121-1 | 2 | 0.4 | 2.5 | 3.3 | 2.8 | 90±20 | |

| 9 | 101281-1 | 2 | 0.4 | 2.5 | 3.5 | 2.8 | 100±35 | |

| 10 | 101009-1 | 2 | 0.4 | 2.5 | 3.5 | 2.9 | 100±30 |